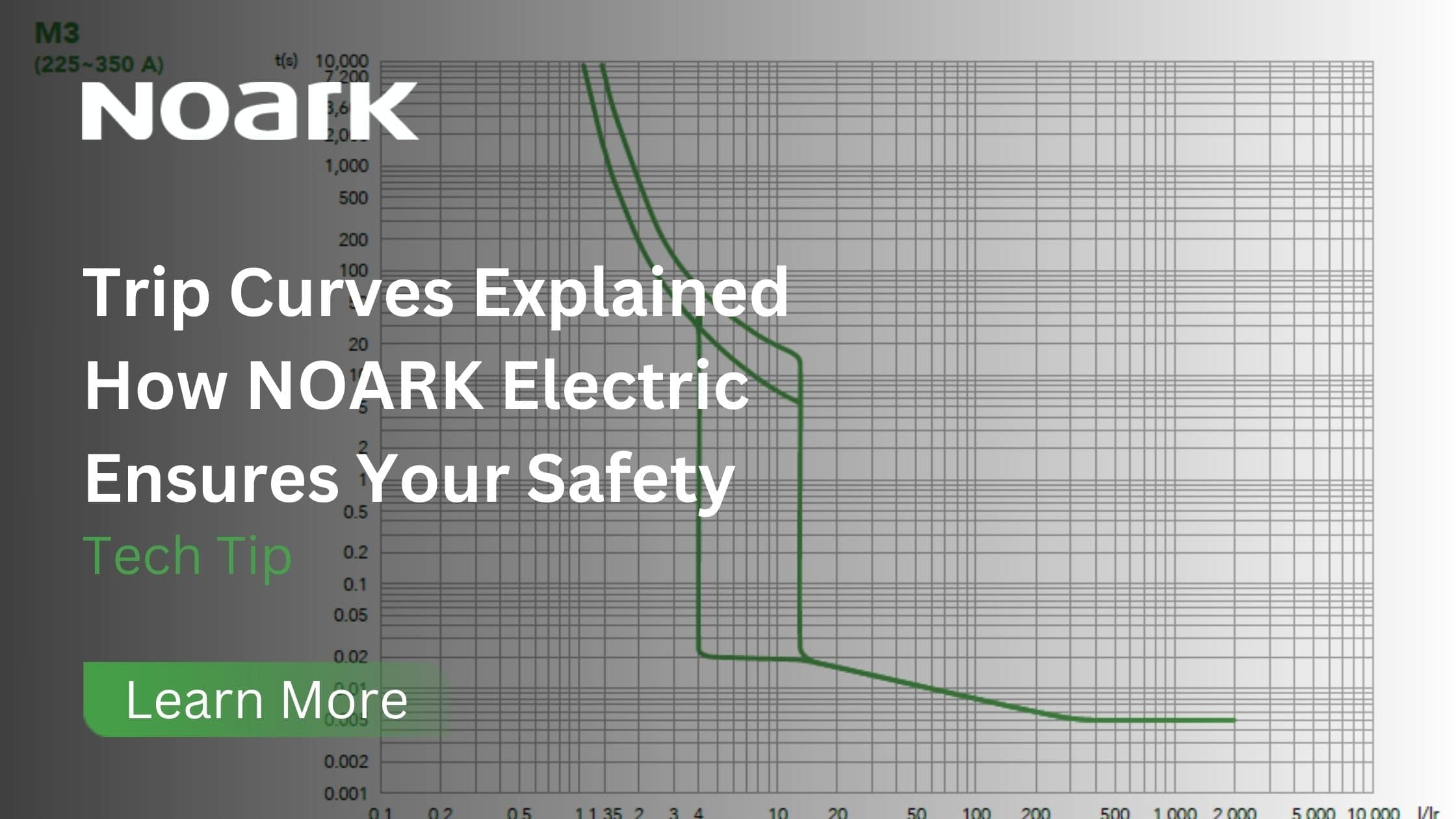

Reduced Voltage Motor Starter Method with NOARK Electric Components

In this blog post, we’ll dive into the reduced voltage motor starter method and explore how NOARK Electric is transforming the electrical industry. Before we jump into the details, let’s quickly recap how motors start. When you turn on a motor, it requires a huge amount of current to overcome starting inertia and get the machine up and running. This initial burst of current is referred to as inrush current. Traditional starting methods often result in high inrush current, causing voltage dips, circuit breaker tripping, and even damage to the motor and connected equipment.

This article will explain the Reduced Voltage method in detail. To learn more about the various other types of motor starting methods, you can learn more in our Understanding General Motor Starting Methods article.

Introducing Reduced Voltage Motor Starting

The reduced voltage motor starter method is one of the most common methods in the electrical industry. Instead of applying full line voltage at startup, this method gradually ramps up the voltage to the motor, reducing inrush current and minimizing the impact on the electrical system.

How Does It Work?

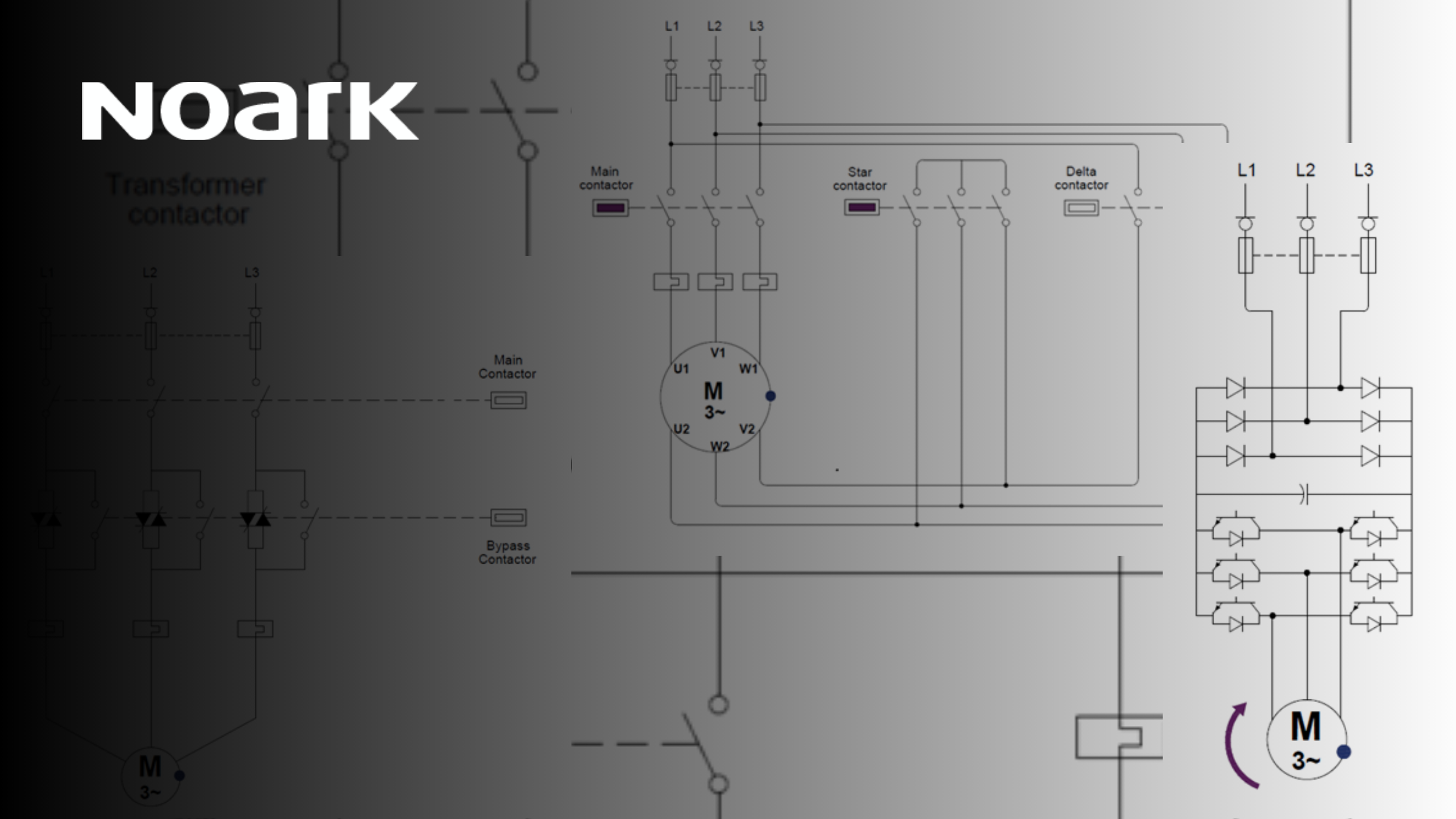

The reduced voltage motor starting method utilizes various schemes and components including a motor starter with a built-in autotransformer with automatic tap changers, contactors connected in star-delta configuration or solid-state device. These components limit the initial voltage supplied to the motor during startup, preventing excessive current flow. As the motor gains momentum, the starter gradually increases the voltage until it reaches the desired operating level. This gentle approach not only protects your motor but also ensures the reliability of your electrical system.

The reduced voltage motor starter method is a technique used to start electric motors with reduced voltage to minimize the inrush current and torque during startup. This method is commonly used to prevent excessive mechanical stress on the motor and the connected equipment.

How Many Types of Reduced Voltage Options are There?

There are several types of reduced voltage motor starter methods, including:

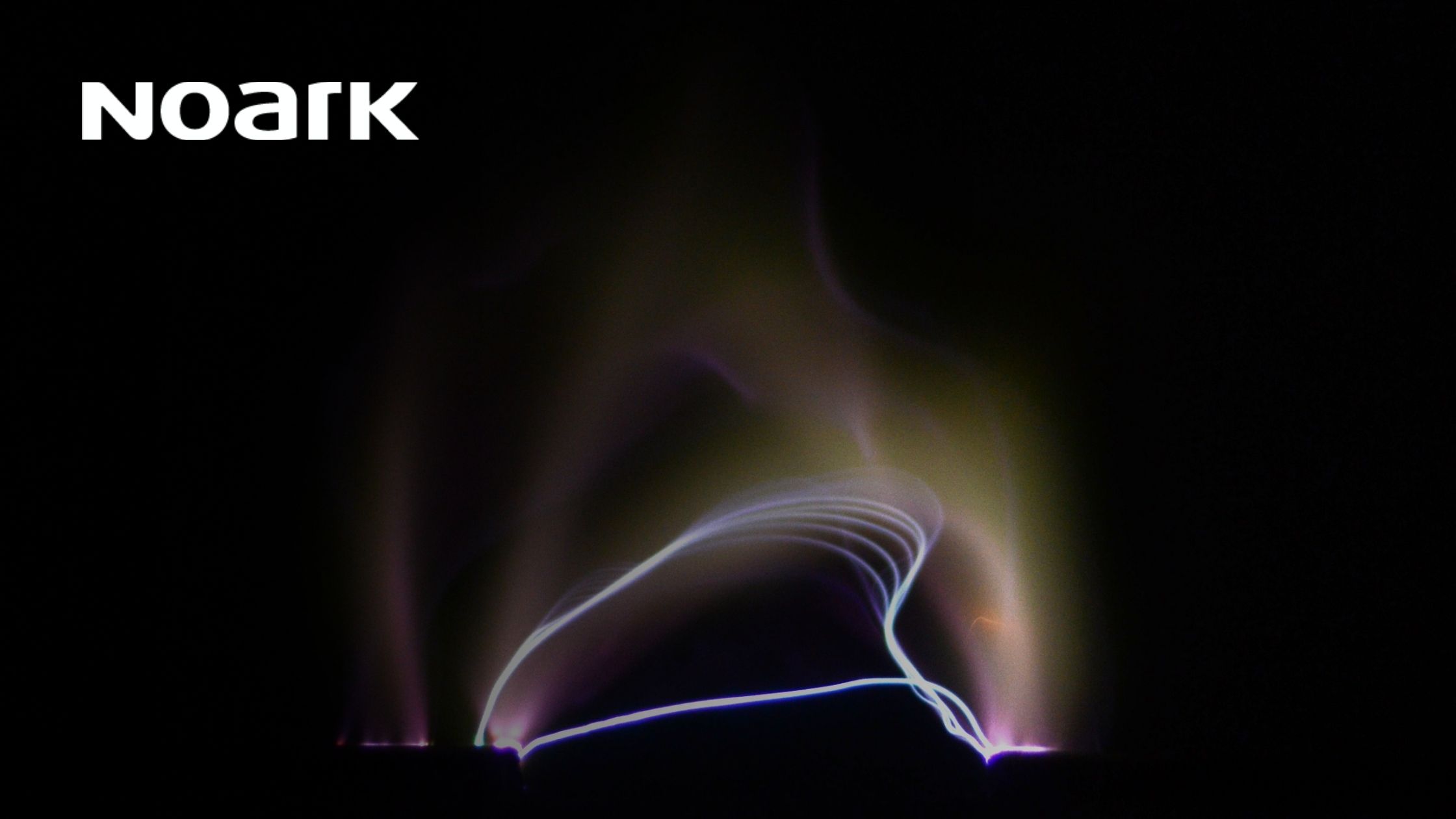

- Autotransformer Starting: This method uses an autotransformer to reduce the voltage supplied to the motor during startup. The autotransformer taps are gradually switched to increase the voltage to the motor, reducing the inrush current. In the picture below, when power is switched on, the transformer and star contactors pull in and are actuated. The transformer contactor energizes the transformer circuit while the star contactor forces the transformer into a star configuration. The tapped output from the transformer is connected across the motor terminals, allowing the motor to start. This output is gradually increased through the auto tap changer until it reaches 85% to 90% of the full voltage and the star contactor drops out. The transformer circuit serves as a choke limiting the amount voltage and current to the motor for a while before dropping off and the main contactor pulls in. The motor then continues to run in the full voltage non-reversing mode.

- Star-Delta Starting: In this method, the motor is initially connected in a star configuration, which reduces the voltage applied to the motor windings. After a certain period, the motor is switched to a delta configuration, which increases the voltage to its rated value. At the start, the main and star contactors pull in, this ensures that the line current across the terminals is about a third of the full motor current. After the motor spins up to nearly the full speed, the star contactor drops out and delta contactor pulls in allowing the motor to continue running at the full motor current and voltage.

- Solid-State Soft Starter: A solid-state soft starter uses solid state electronics to gradually increase the voltage supplied to the motor during startup. This method provides a smooth acceleration and reduces the inrush current. Once the motor has reached its full speed, the soft starter hands off to a bypass contactor but continues to monitor the current and voltage. The bypass contactor can either be in-built with the soft starter or an external bypass.

- Variable Frequency Drive (VFD): A VFD is a multi-speed motor controller that adjusts the frequency and voltage supplied to the motor. By gradually increasing the frequency and voltage, a VFD can provide a controlled startup with reduced inrush current.

These methods are used based on the specific requirements of the motor and the application. The choice of the reduced voltage motor starter method depends on factors such as motor size, load characteristics, and the desired starting torque.

Leveraging NOARK Electric Components for Your Reduced Voltage System

NOARK Electric’s soft starters are ideal for reduced voltage starting in motor-driven applications. Our units have the ability to minimize inrush current and protect equipment, ensuring a smooth and efficient startup which will enhance both the performance and reliability of your electrical power systems.

So, whether you’re in the industrial, commercial, or residential sector, it’s time to bid farewell to those abrupt starts and embrace the reduced voltage method using NOARK’s components. Your motors will thank you, and your electrical system will thank you too!

Liked this article? Sign up for our free NOARK Newsletter to stay up to date on new product launches, get insider access to more tech tips like this one, and to receive free downloadable resources.